Applied tools and approaches

Both mathematical models and in-house developed computer programs, as well as CFD calculations and experimental studies on stands are used for problem solving.

Experimental capabilities:

We have 6 experimental benches at our disposal, including a unique closed-loop bench with power up to 600 kW, revolutions up to 18000 per minute, impeller diameters up to 420 mm.

CFD calculations and multi-parameter optimization:

CFD programs are used for finalization and improvement of designed flow parts, research of supersonic flows in impellers of centrifugal and axial compressors, analysis of axial forces and stresses.

Mathematical models of our own development:

We have developed and patented more than 25 computer programs and mathematical models solving a wide range of problems:

- program of optimal design of multi-shaft multistage centrifugal compressors with intermediate cooling;

- program for calculating a family of gas dynamic characteristics of a centrifugal compressor.

- program for calculation of efficiency and main dimensions of axial compressor;

- program for calculation of efficiency and main dimensions of axial fan.

Activities:

- optimal gas-dynamic design of compressors according to the assignment of compressor equipment manufacturers

- experimental research and finalization of turbocharger flow parts

- analysis of technical condition of compressors and recommendations for modernization and operation

- certification of purchased compressors

- development of digital doubles of compressor equipment and their systems in the interests of consumers and compressor manufacturers

- reliability and diagnostics of compressor equipment

- pneumatic audits or surveys of compressed air networks and plant equipment

- Calculation and design of vacuum systems

- development of wide-range vacuum gauges

- development of ultra-high vacuum pumping units

- research in ultra-high vacuum environment

- conducting advanced training courses in the field of compressor, vacuum and refrigeration technology and pneumatic systems.

Several dozens of compressors (2000 - 25,000 KW, 1-8 stages, with final pressure up to 12.5 MPa) were designed for national and international customers - about 400 units with a total installed capacity of about 5 million kW were produced.

Current projects:

- “Research and gas-dynamic design of air twin-shaft centrifugal compressor CK 100/11 VT of “Veltex” Ltd. 2022, contract No. VEL/PR 22-22 of 30.03.2022

- Research of characteristics and optimal design of compressor TK26 JSC “Turboholod”, contract No. 1208/2022TBH of 12.08.22 2022.

Completed projects:

- Gas-dynamic calculations and determination of design parameters of elements and assemblies of TDCA, contract №140306503 with ZAO Internevmash. 2006 г.

- Calculated research of efficiency of elementary grids of axial compressors using experimental data on influence of diffusivity factor. Contract №140306710 with KIROV-Energomash plant. 2007 г.

- Designing of the flow part of the compressor stage for turbo-detander unit for rotation frequency 13000-15000 rpm. Contract ¹140306711 withTurbogaz, Kharkov, Ukraine 2007-2008.

- Research and analysis of efficiency of gas-dynamic and design parameters of GPA axial compressors in order to determine the rational field of application. Contract ¹140306312 with OAO Gazprom, 2007-2008.

- Calculation analysis of increasing the efficiency of linear, booster and UGS natural gas blowers by increasing the rotation speed. OAO Gazprom. 2009г.

- Research and efficiency analysis of gas-dynamic and design parameters of GPA axial compressors in order to determine the rational field of application. Contract No. 140306712 with OAO Gazprom. 2009г.

- Development of the mathematical model of the pressure characteristic of the centrifugal compressor wheel based on the results of experimental studies and calculations of the non-viscous quasi three-dimensional flow. Federal Agency for Science and Innovations 2009 - 2010 gg.

- JSC “Turboholod” Optimization of flow part and gas-dynamic design of TK3 centrifugal compressor modernization for reduced speed of rotation2010

- Aerodynamic design of axial fans for turbogenerators with hydrogen-water cooling. Contract №140306002 with OJSC “Power Machines - Elektrosila” 2010.

- Designing of flow part of single-stage centrifugal compressor with axial impeller for 32 MW GPA. Sumy NPO named after M.V.Frunze. 2012 г.

- JSC “Turboholod” Optimization of flow part and gas-dynamic design of centrifugal compressor TK10 - 1,32/10,0 2012

- JSC Turboholod Optimization of flow part and gas-dynamic design of centrifugal compressor TK11 - 1.22/10.1 2012

- JSC “Turboholod” Project of TK11A compressor - adjustment of IF TK11 - 1,22/10,1 for changed initial parameters 2012

- JSC “Turboholod” Optimization of flow section and gas dynamic design of TK-12 centrifugal compressor 2012

- Development of model stages of high efficiency for flow parts of centrifugal compressors. Sumy NPO named after M.V.Frunze. 2012 г.

- Designing of six-stage replacement flow part of centrifugal compressor SPCH-Ts-16S/30-3.0 with increased reserve on pumpage” M.V.Frunze Sumy NPO. 2013

- Designing of replacement flow part SPCH-Ts-16C-16/30-3.0 for application in centrifugal compressors with magnetic bearings Sumy NPO named after M.V.Frunze 2013.

- “Improvement of technology of creation of high-pressure axial compressor stage of small-size GTE. Contract No. 753.20.1.547 with JSC “Klimov” 2013.

- Development of a general methodology for creating high-pressure compressors based on modern methods of aerodynamic calculations”. Contract No. 753.20.1.548 with OJSC “Klimov” 2013.

- JSC “Turboholod” Optimization of flow section and gas-dynamic design of centrifugal compressor TK-13 2013

- JSC “Turboholod” Gas-dynamic design of TK-14A centrifugal compressor based on the design of TK-11A compressor 2013

- Optimization of flow part and gas-dynamic design of centrifugal compressor TK-15 “Chayand” for summer and winter modes of operation JSC Turboholod 2014

- Increase of centrifugal compressor flow part efficiency and design recommendations on the basis of computational gas dynamics calculations. Federal Agency for Science and Innovations 2015 - 2016.

- Optimization and design of a replaceable flow part of SPF HC - 16-76-1,35 with spatial impellers. Iskra-AVIGAZ 2015 under contract No. 144503401 of 16.06.2014.

- Optimization and design of centrifugal stage No.1 for a four-stage compressor type CBK 25-757-48-1. JSC Iskra-Avigaz 2015 under contract No. 144405502 of 11.09.2015

- JSC Iskra-Avigaz Creation of a modern high-tech production facility for the design, manufacture, testing, installation of units compressing gaseous products for efficient use in transportation systems and technologies” 2016 (1,2 stages) 316-2005/2015 dated 22.07.2015

- NPO “Klimov” Development of compressor, high and low pressure turbine design by calculation method, providing technical characteristics presented in technical requirements.

- JSC “Turboholod” Verification calculation, refinement of gas dynamic parameters and profiling of TK-4M centrifugal compressor “SPCH-M-BOV 2017

- Gas-dynamic design of centrifugal compressor TK-17 SPCH-M-BOV JSC “Turboholod” 2017 Contract No. 59-11/2017 TBH dated 10.10.201

- JSC “Turboholod” Optimization and gas-dynamic design of centrifugal compressor TK 18 for a given speed of rotation 15500 r/min” 2018 under contract No. 26-05/2018 of 08.05.2018

- JSC “Turboholod” Optimization and gas-dynamic design of centrifugal compressor TK19 for a given speed of rotation 17500 r/min 2019 under contract No. 18022019/1-TBH from 28.02.2019

- Development of technical solutions and prototypes of devices - combustion chamber, low-pressure compressor for creation of competitive gas turbines with the capacity of 25 MW for gas pumping units on the basis of digital twins of the developed devices A. Lulka Design Bureau 2019 (General title “Development of technical solutions and prototypes of devices - combustion chamber, low-pressure compressor for creation of competitive gas turbines with the capacity of 25 MW for gas pumping units on the basis of digital twins of the developed devices”).

- Optimization and gas dynamic design of TK22 centrifugal compressor for a given speed of 13500 rpm. Calculation of gas dynamic characteristics at 15 modes JSC “Turboholod” 2020 under contract No. TBH10062020-1 of 10.06.2020

- Research of characteristics and optimal design of compressors TK23 and TK24 (two compressors for TDA Evo-Yakhinskoye) JSC “Turboholod” 2021 under contract No. TBH11052021 from 11.05.2021.

- Optimization and gas-dynamic design of centrifugal compressor TK27 with calculation of 6 modes. JSC “Turboholod” 2021 under Contract No. TBH23072021 of 23.07.2021

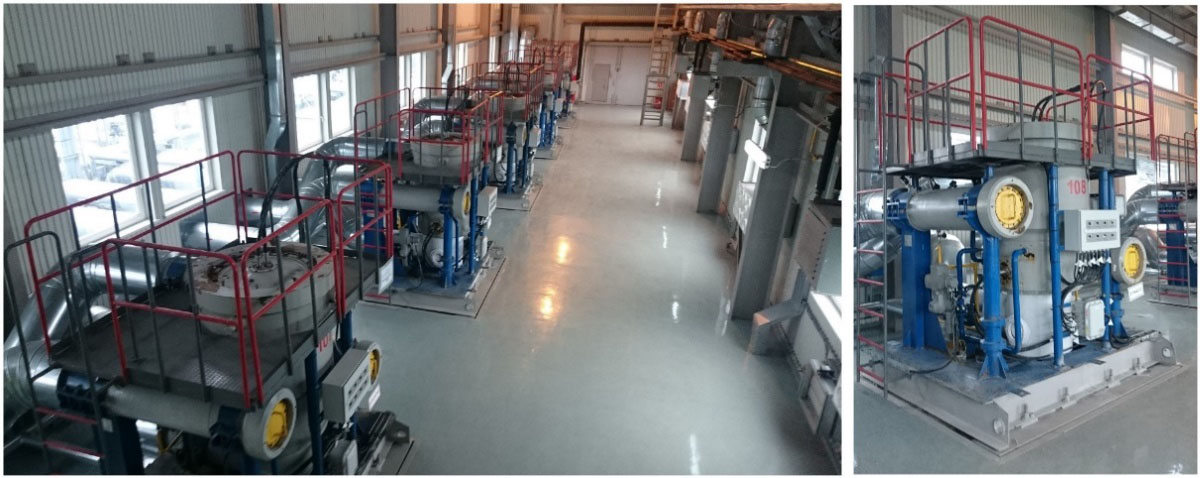

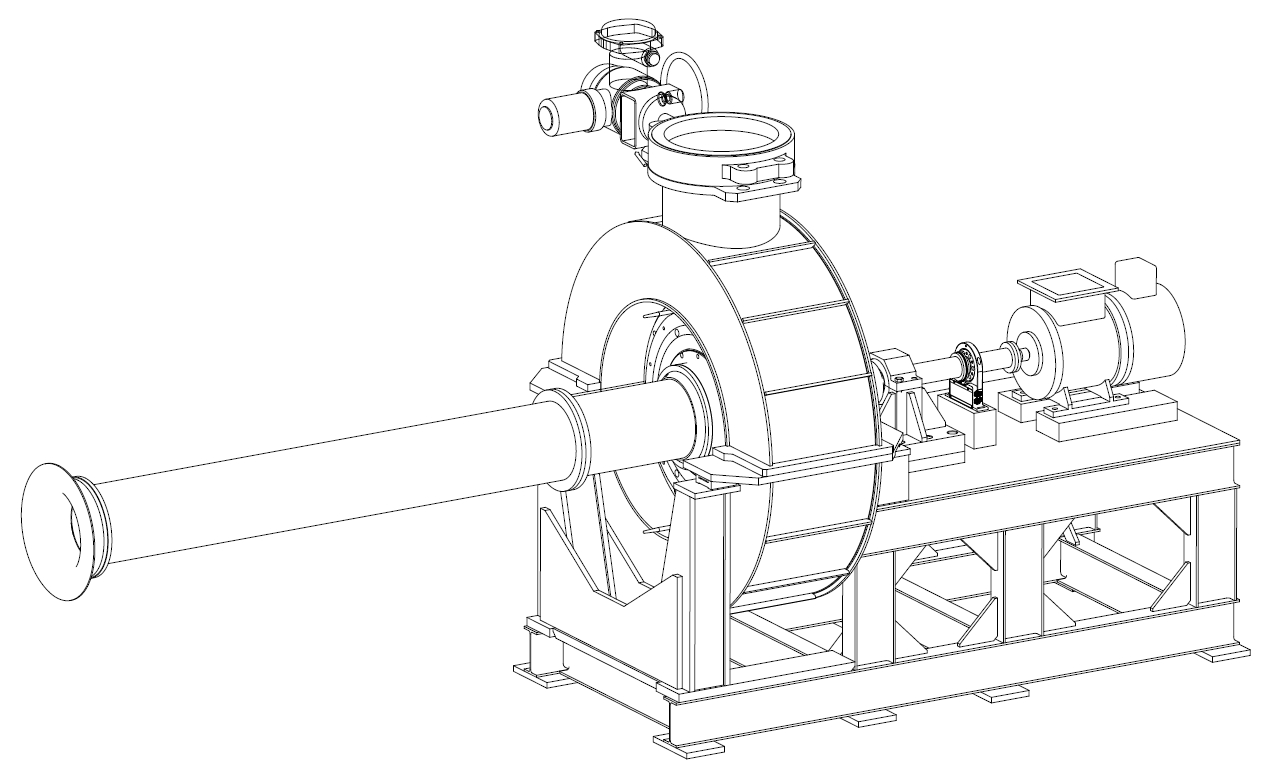

ADKG-10-20-20-UHL4 tubodetander units at COGS CS-42 Yarynskaya MG Bovanenkovo-Ukhta

Experimental benches of the compressor engineering laboratory

There are unique experimental benches (ECC-55, ECC-4, ECC-5, ECC-8, ECC-1) designed for experimental studies of model compressor stages and gas flow in them.

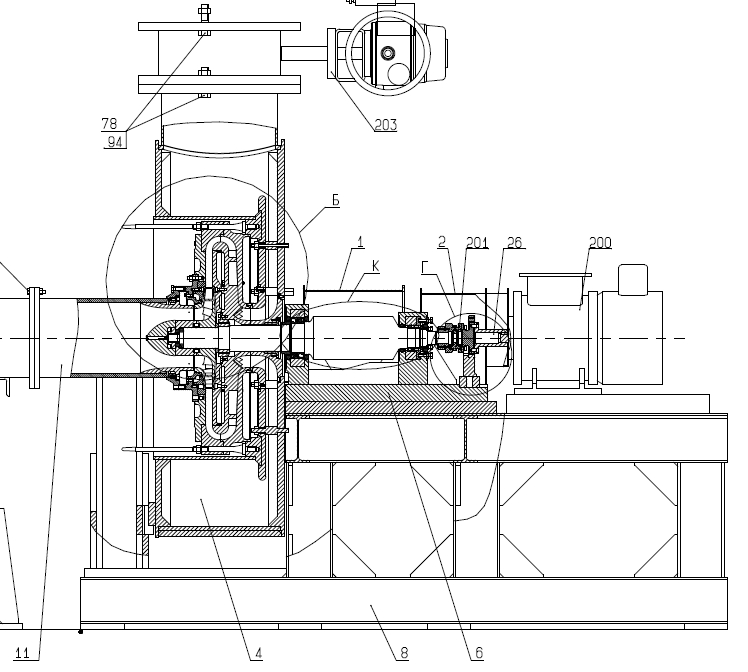

The most modern is the experimental stand Etsk-55. To process experimental data the computer program RIMS-55 was created for the stand. It is designed to plot gas dynamic characteristics of the tested object in real time. The high-frequency electric motor with the power of 55 kW drives the rotor with the number of revolutions up to 10500 per minute. Model stage impellers with a diameter of 350 mm can have a design flow coefficient of up to 0.15. The electronic measuring system provides measurement of the gas dynamic characteristics of the stage within a few minutes. Adjustment tests confirmed the performance of the stand and systems.

The model stage casing can be replaced independently from the rest of the test bench for testing stages of other design. Axial suction on the side opposite the shaft bearings facilitates access to the labyrinth seal of the covering disk.

The rotor is supported by twin SKF precision angular contact ball bearings. The model housing and bearing housing are mounted independently on the frame to eliminate deformation of the bearing housing from the massive model housing. The shaft is driven into rotation through a dry plate coupling from a frequency-controlled asynchronous electric motor. The electric motor is powered by a Danfoss VLT series frequency converter.

Static pressure receivers are located in 6 points evenly around the circumference to measure flow parameters in the control sections. To measure the air flow rate, a narrowing device in the form of a lemniscate is installed at the end of the suction pipe.

The pressures through fittings are taken out of the flow part and are fed by flexible rubber tubes to the electronic pressure transducers of PR-33 and PR-41 types, manufactured by Keller with the basic measurement error of 0,05% of the upper measurement limit.

The measurement of torque, to determine the work transmitted to the impeller, is necessary to determine the efficiency of the stage. This is a modern alternative to the approach based on the measurement of the total temperature change in the stage, which requires a long stand time to reach the steady-state thermal regime and gives a significant error at a small ratio of pressures in the stage. On the stand ECK-55 torsiometer of flange type T40B of HBM company is applied.

The PR-33 and PR-41 transducers convert the measured pressure into a digital electric signal and incorporate thermocompensation circuits during measurements. The output signal of pressure transducers is transmitted via RS-485 digital interface to the automated pressure measurement system via RS485-USB converter.

The rotation speed is controlled by a Danfoss frequency converter, VLT series, and is monitored by an electronic tachometer of VEHA-T type.

For compensation of linear and angular misalignment of shafts the Roba-DS plate coupling of Mayr company recommended by the torsiometer manufacturer is used. The T40B torsiometer has a measuring limit of 100 Nm, with an allowable shaft speed of 20000 rpm and a basic error of 0.01%.

The torque measured by the torsiometer sensing element is transmitted by contactless method to the stator part of the torsiometer, where it is converted into a frequency signal, which is transmitted to the measuring system. As an amplifier-converter of the frequency output signal of the torsiometer T40B, a HBM device model MPE MP60 is used. The MP60 unit receives the tare characteristic from the torsiometer data sheet. The torque value is transmitted to the computer via the high-speed digital data bus CAN-bus, through the CAN bus-USB interface converter.

Research team members

Publications:

- Grigoriev A.V., Solovyova A.V., Galerkin Y.B., Popov Y.A. Computer program for calculation and initial design of supersonic stages of axial compressors. Compressor engineering and pneumatics. - 2014. - № 4. - С. 29-35.

- Galerkin Yu.B., Rekstin A.F., Soldatova K.V., Drozdov A.A. Highly effective single-stage full-pressure compressor of GPA (gas-dynamic project, the result of model tests). Compressor engineering and pneumatics. - 2014. - № 8. - С. 19-25.

- Galerkin Y.B., Rextin A.F., Soldatova K.V., Drozdov A.A. Radial and axial impellers of centrifugal compressors - advantages, disadvantages, application area. Compressor technique and pneumatics. - 2015. - № 7. - С. 23-32.

- Galerkin Yu.B., Rextin A.F., Soldatova K.V. K discussion of the methods of factory tests of gas centrifugal compressors. Compressor engineering and pneumatics. - 2016. - № 2. - С. 12-17.

- Galerkin Yu.B., Rextin A.F., Soldatova K.V., Drozdov A.A. Analysis of geometrical and gas-dynamic parameters of centrifugal compressor stages in the tenfold range of the design flow coefficient. Compressor engineering and pneumatics. - 2016. - № 7. - С. 32-43.

- Bakaev B.V., Pisarev Y.N., Lysyakova A.A., Lentsman M.M., Galerkin Y.B., Rextin A.F., Drozdov A.A. Centrifugal compressors of perspective GCU: parameter selection and example of compressor design. Journal of SFU. Technics and technology. - Krasnoyarsk. - 2017. -С. 1062-1078

- Rekstin A.F., Semenovsky V.B., Soldatova K.V., Galerkin Y.B., Sokolov K.K. Features of modeling of gas-dynamic characteristics of centrifugal compressors of turboexpander units. Compressor engineering and pneumatics. - 2018. - №1. - С. 13-20.

- Rextin A.F., Popova E.Yu., Utsekhovskiy A.A. Efficiency analysis of centrifugal compressor stages with the help of approximate algebraic equations. Compressor technology and pneumatics. - 2018. - №1. - С. 33-40.

- Borovkov A.I., Voinov I.B., Nikitin M.A., Galerkin Y.B., Rextin A.F., Drozdov A.A. Modeling of characteristics of a single-stage centrifugal compressor of a gas pumping unit. // Scientific and Technical Vedomosti SPbPU. Natural and engineering sciences. 2018. Т. 24, № 3. С. 153-175. DOI: 10.18721/JEST.240313

- Semenovsky V.B. Model stages for centrifugal compressors of turboexpander units. // Scientific and Technical Vedomosti SPbPU. Natural and engineering sciences. 2018. Т. 24, № 4. С. 11-23. DOI: 10.18721/JEST.24402

- Rekstin A.F., Soldatova K.V., Galerkin Y.B. Verification of the simplified mathematical model of centrifugal compressor stages. Izvestiya vysshee obrazovaniye uchebnykh obrazovaniye - #9(702)/2018 - Moscow, Bauman Moscow State Technical University - 2018.- DOI: 10.18698/0536-1044-2018-9-44-56

- Rekstin A.F., Drozdov A.A., Solovyova O.A., Galerkin Y.B. Comparison of two mathematical models of a vane-less diffuser of a centrifugal compressor stage. Compressor engineering and pneumatics. - 2019. - №1. - С. 2 - 10.

- Semenovsky V.B., Rextin A.F., Galerkin Yu.B., Sokolov K.K. Experimental and calculation studies of a series of centrifugal compressors of a turboexpander unit. Izvestiya vysshee obrazovaniye uchebnykh obrazovaniye - #1(706)/2019 - Moscow, Bauman Moscow State Technical University - 2019.- DOI: 10.18698/0536-1044-2019-1-37-47 P. 37-47

- Borovkov A.I., Voinov I.B., Rextin A.F., Bakaev B.V. Modeling of the characteristics of a two-stage centrifugal compressor of a gas pumping unit // Scientific and Technical Vedomosti SPbPU. Natural and engineering sciences. 2019. Т. 25, № 2. С. 87-104. DOI: 10.18721/JEST.25207

- Petukhov E.P., Galerkin Yu.B., Rekstin A.F. Investigation of methods of testing vane diffusers of centrifugal compressor stages in a virtual wind tunnel. Izvestiya vysshee obrazovaniya vysshee obrazovaniya. Mashinostroenie, 2019, No 8, pp. 51-64, doi: 10.18698/0536-1044-2019-8-51-64

- Borovkov A.I., Voinov I.B., Galerkin Y.B., Drozdov A.A. Results of modeling of gas dynamic characteristics of low-flow and medium-flow model stages for industrial centrifugal compressor. Izvestiya vysshee obrazovaniya vysshee obrazovaniya. Mashinostroenie, 2019, No 9, pp. 77-87, doi: 10.18698/0536-1044-2019-9-77-87

- Galerkin, Y., Popov, Y., Drozdov, A., Semenovskiy, V., Soldatova, K., Bezborodov, A. Three-dimensional flow analysis in “non-homogeneous” axial compressor stages. Journal of Advanced Research in Dynamical and Control Systems. Volume 11, Issue 8 Special Issue, 2019, Pages 2905-2915 (axial SCOPUS)

- Galerkin Y.B., Rextin A.F., Soldatova K.V., Drozdov A.A., Solovyova O.A., Semenovsky V.B. State of engineering method of optimal gas-dynamic design and calculation of centrifugal compressor characteristics. Part 1. Compressor engineering and pneumatics. - 2019. - №4. - С. 3 - 10.

- Borovkov, A., Galerkin, Y., Popov, Y., Rekstin, A., Semenovskiy, V., Soldatova, K. Efficiency analysis of blade cascades of axial compressors by the results of wind tunnel test. Journal of Advanced Research in Dynamical and Control Systems. Volume 12, Issue 1 Special Issue, 2020, Pages 953-961.

- Drozdov A.A., Galerkin Yu.B., Utsekhovsky A.A. Development and Implementation of the New Mathematical Model of Tangential Output Devices of Centrifugal Compressors. - Izvestiya vysshee obrazovaniya vysshee obrazovaniya. Mashinostroenie. - #6(723)/2020 - Moscow, Bauman Moscow State Technical University - 2020 - DOI: 10.18698/0536-1044-2020-6-17-35

- Galerkin Y.B., Rextin A.F., Soldatova K.V., Drozdov A.A., Solovyova O.A., Semenovsky V.B. Modern state of engineering method of optimal gas-dynamic design and calculation of centrifugal compressor characteristics. Part 2. Compressor Engineering and Pneumatics. - 2020. - №1. - С. 8 - 11.

- Galerkin Y.B., Rextin A.F., Soldatova K.V., Drozdov A.A., Solovyova O.A., Semenovsky V.B. Modern state of engineering method of optimal gas-dynamic design and calculation of centrifugal compressor characteristics. Part 3. Compressor Engineering and Pneumatics. - 2020. - №2. - С. 2 - 9.

- A. I. Borovkov, Yu. B. Galerkin, O. A. Solovieva, A. A. Drozdov, A. F. Rekstin, K. V. Soldatova, A. A. Sebelev. Methodology and experience of primary design of a transonic axial compressor. WSEAS Transactions on Systems and Control, ISSN / E-ISSN: 1991-8763 / 2224-2856, Volume 15, 2020, Art. #44, pp. 439-452 https://doi.org/10.37394/23203.2020.15.44

- A.I. Borovkov, Yu. Galerkin, Yu.A. Popov, A.F. Rekstin, O.A. Solovyeva, A.A. Drozdov, L.N. Marenina, V.A. Chernikov. Analysis of the efficiency of elementary grids of axial compressors based on the data of flat grid purges. WSEAS Transactions on Applied and Theoretical Mechanics, E-ISSN: 2224-3429, Volume 15, 2020, DOI: 10.37394/232011.2020.15.14.

- A.I. Borovkov, Yu. Galerkin, Yu.A. Popov, A.F. Rekstin, O.A. Solovyeva, A.A. Drozdov, L.N. Marenina, V.A. Chernikov. Computational Analysis of Axial Compressor Stages Characteristics. WSEAS Transactions on Applied and Theoretical Mechanics, E-ISSN: 2224-3429, Volume 15, 2020, DOI: 10.37394/232011.2020.15.13.

- Yu. Galerkin, A. Rekstin, K. Soldatova, A. Drozdov, O. Solovyeva, V. Semenovskiy, and L. Marenina. Marenina. The current state of the engineering method for the optimal gas-dynamic design and calculation of centrifugal compressor. Energies 2020, 13(21), 5651; https://doi.org/10.3390/en13215651.

- Yu. Galerkin, A. Rekstin, L. Marenina, A. Drozdov, O. Solovyeva, V. Semenovskiy. Optimization of return channels of high flow rate centrifugal compressor stages using CFD methods. Energies 2020, 13(22), 5968; https://doi.org/10.3390/en13225968.

- Borovkov, A., Voinov, I., Galerkin, Yu., Kaminsky, R., Drozdov, A., Solovyeva, O., Soldatova, K. Design, Plant Test and CFD Calculation of a Turbocharger for a Low-Speed Engine. Appl. Sci. 2020, 10, 8344. https://doi.org/10.3390/app10238344

- Borovkov, A.I.; Galerkin, Yu.B.; Solovyova, O.A.; Drozdov, A.A.; Rextin, A.F.; Semenovsky, V.B.; Brodnev, P.N. Development of the mathematical model and the computer program of the primary design of the transonic axial compressors / / Omsk Scientific Bulletin. Ser. Aviation-missile and power engineering. 2020. Т4, № 4. С. 16-27. DOI:10.25206/2588-0373-2020-4-4-16-27

- O. Solovyeva, Yu. Galerkin, A. Rekstin, K. Soldatova, V. Yusha, K. Kabalyk. Centrifugal compressor stage. Vaneless diffuser preliminary design by universal modeling method. International Journal of Mechanical and Production Engineering Research and Development. - Vol. 10, Issue 3, Jun 2020, 14879-14894, DOI : 10.24247/ijmperdjun20201417

- L.N. Marenina, O.A. Solovyeva, A.A. Drozdov, Yu. Galerkin, V.L. Yusha, K. Kabalyk. Creation of parametrized model of transonic axial compressor flow path for CFD-researches. International Journal of Mechanical and Production Engineering Research and Development. - Vol. 10, Issue 3, Jun 2020, 15095-15104, DOI : 10.24247/ijmperdjun20201438

- A. A. Kotlov, A. A. Drozdov, V. B. Semenovskiy, K. Kabalyk. Software systems for visualizing the centrifugal compressor stages flow path and creating 3D models of impellers. International Journal of Mechanical and Production Engineering Research and Development. - Vol. 10, Issue 3, Jun 2020, 14969-14982, DOI : 10.24247/ijmperdjun20201426

- A.I. Borovkov, Y.B. Galerkin, A.A. Drozdov, A.F. Rextin, V.B. Semenovsky, V.K. Yadykin. Stand ECK-55 with direct high-frequency drive for gas-dynamic investigations of industrial centrifugal compressors. Compressor Engineering and Pneumatics. - 2020. - №4. - С. 4 - 13.

- Solovyova O.A., Soldatova K.V., Galerkin Y.B., Rekstin A.F. Primary design of bladeless diffusers of centrifugal compressor stages by the method of universal modeling. - Izvestiya vysshee obrazovaniya vysshee obrazovaniya. Mashinostroenie. - #3(732)/2021 - Moscow, Bauman Moscow State Technical University - 2021 - DOI: 10.18698/0536-1044-2021-3-39-52

- Babichenko I.A., A.A. Mikhailov, K.K. Sokolov, A.I. Borovkov, Y.B. Galerkin, I.A. Maksimenko, A.F. Rextin, V.B. Semenovsky, V.K. Yadykin. Experience of Gas Dynamic Design of Centrifugal Compressors of Turboexpander Units. CFD-analysis of the inlet path // Materials Science. Power Engineering. 2021. Т. 27, № 2. С. 5-22. DOI: 10.18721/JEST.27201

- A. Borovkov, Yu. Galerkin, E. Petukhov, A. Drozdov, V. Yadikin, A. Rekstin, V. Semenovskiy, O. Solovyeva, L. Marenina. CFD researches of centrifugal compressor stage vane diffusers in interests of math modeling. Int J Adv Manuf Technol (2021). https://doi.org/10.1007/s00170-021-07335-5

- Galerkin Yu.B., Drozdov A.A., Rextin A.F. O.A. Solovyova, L.N. Marenina. Mathematical Model of Universal Modeling Method for Calculation and Design of Centrifugal Compressors: Identification and Verification by Experimental Data. Vestnik MSTU named after N.E. Bauman. Ser. Mashinostroenie, 2022, No. 1 (140), pp. 82-102. DOI: https://doi.org/10.18698/0236-3941-2022-1-82-102

- Galerkin Yu.B., Rekstin A.F., Drozdov A.A., Marenina L.N. Influence of gas motion in gaps “Impeller-hull” of centrifugal compressor stage on efficiency and axial force. Global Energy. 2022. Т. 28, № 4. С. 7-20. DOI: https://doi.org/10.18721/JEST.28401

- Galerkin Y.B., Rextin A.F., Solovyova O.A. Bladeless diffuser of low-flow centrifugal compressor stage. - Application No. 2017147064 for granting a patent of the Russian Federation for utility model “” with priority date of 29.12.2017.

- Galerkin Yu.B. Computer program “Design and optimization of single shaft non cooled centrifugal compressor”. Exhibit No. 2019662772, registration date 02.10.2019.

- Galerkin Yu.B., Drozdov A.A., Rekstin A.F. Computer program “Centrifugal compressor performance map calculation”. Certificate No. 2019662921, registration date 07.10.2019.

- Galerkin Yu.B., Drozdov A.A. Computer program “Centrifugal stage Performance calculation”. Certificate No. 2019662981, registration date 08.10.2019.

- Galerkin Y.B., Rextin A.F. Computer program “Program for estimation of centrifugal compressor stage performance coefficient by design parameters and similarity criteria”. Certificate No. 2019662982, registration date 08.10.2019.

- Galerkin Yu.B., Drozdov A.A. Computer program “Optimal Design of Centrifugal Compressor”. Certificate No. 2019663034, registration date 08.10.2019.

- Galerkin Yu.B. Computer program “Optimal design of centrifugal stage”. Exhibit No. 2019663554, registration date 08.10.2019.

- Galerkin Yu.B., Drozdov A.A., Solovyova O.A. Computer program “Program for analysis of spatial flow of axial stages”. Certificate No. 2020617605, registration date 08.07.2020.

- Galerkin Y.B., Rextin A.F., Semenovsky V.B. Computer program “Program for calculation of supersonic axial compressor stage”. Certificate No. 2020617670, registration date 10.07.2020.

- Galerkin Yu.B., Drozdov A.A. Computer program “Program for calculation of the family of characteristics of centrifugal compressors RSHTSK-G5”. Certificate No. 2020617671, registration date 10.07.2020.

- Galerkin Yu.B., Drozdov A.A., Rekstin A.F. Computer program “Calculation of efficiency factor and main dimensions of axial blower of gas pumping unit”. Certificate No. 2020617672, registration date 06.07.2020.

- Galerkin Yu.B., Drozdov A.A., Semenovsky V.B. Computer program “Calculation of efficiency factor and main dimensions of axial compressor DOK-GP09”. Certificate No. 2020617744, registration date 10.07.2020.

- Voinov I.B., Keresten I.A., Zakirov O.A., Drozdov A.A. Computer program “Program for automated construction of the flow part of the centrifugal compressor stage”. Certificate No. 2020665490, registration date 27.11.2020.

- Galerkin Y.B., Rextin A.F., Drozdov A.A., Solovyova O.A., Semenovsky V.B. Computer program “Program for variant calculation of centrifugal compressor of turboexpander unit”. Certificate No. 2021617552, registration date 17.05.2021.

- Galerkin Y.B., Drozdov A.A., Rekstin A.F. Computer program “Program for optimization of flow part and calculation of characteristics of industrial centrifugal compressor”. Certificate No. 2021617416, date of registration 14.05.2021.